Electroplating & Anodizing

Table of Contents

Electroplating

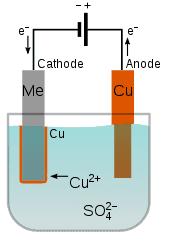

Electroplating covers a product with a coat of metal with the help of electricity. The coating metal material was initially placed on the cathode of the process, and it must be more reactive than hydrogen and less reactive than the cathode material.

Throughout the process, an external power source is connected to induce the flow of charges from the anode to the cathode.

The metal anode ionizes into the solvent, which is a solution of the anode.

The charges 'pulled' from the anode are pushed onto the cathode, where the ionized metals are finally de-ionized and deposit to create a layer of the anode metal material.

Electroplating is done for numerous reasons,

One of the main functions of electroplating your product is to prevent corrosion and oxidation which damages the product.

Another function of electroplating is to increase the heat resistance of the product.

Increase the strength of the underlying material if the material is initially brittle.

If the underlying material is strong and expensive, the coating material used could serve as the sacrificial layer to protect the material from being tarnished.

Metals and plastics are both eligible for electroplating. NexPCB's common plating materials are copper, nickel, gold, chromium, and silver - with the common finishing color of black or metallic.

Anodizing

Anodizing is an electrochemical process, done very similarly to electroplating to cover a metal's surface with the oxide of the base material. This is done commonly to aluminum to prevent tarnish and corrosion of the base material.

During the electroplating process, the target object serves as the cathode of the electrochemical cell, while during the anodizing process, the object serves as the anode. Anodizing can be done on a selection of materials, including aluminum, titanium, other similar metals, and alloys. They have no size limitation and can provide different coating colors.

NexPCB provides 2 types of anodizing processes:

- Oxalic acid anodizing

In oxalic acid anodizing, the layer created is yellowish.

- Sulfuric acid anodizing

When using the sulfuric acid anodizing method, the layer created is transparent.

Despite the yellow or transparent color provided by the oxidation of the metals, adding different colors to your workpiece is also possible by adding dyes into the anodizing solvent.

Related Articles