Packaging Design

Packaging is the embodiment of brand concepts and product markers. It acts as a bridge to communicate the products' features to the consumers.

Product packaging is designed to protect the product, convey information about the product, promote its use, facilitate transportation, market the product, etc.

Packaging Materials

The most commonly used packaging materials include:

- White paper, e.g. ordinary white paper, copy paper, crepe paper, etc.

- Bubble wrap / sponge / pearl cotton

- Carton paper box, e.g. plain white carton, plain brown carton, colored carton, etc.

- Plastic bags, e.g. PP, PE, OPP, PVC, PVA, shrink film (PE, PP), etc.

There are many other packaging materials, which are usually all supported by auxiliary materials such as adhesives, coatings, inks, and many more.

The material selection for a green packaging design should satisfy the following principles:

- It should be lightweight, thin, easily disassembled, and robust.

- It should be biodegradable.

- It should be easily broken down.

- It should use ecological energy packaging materials, which are organic.

- Paper packaging as much as possible

Forms of Packaging

Here are some of the most commonly used types of packaging:

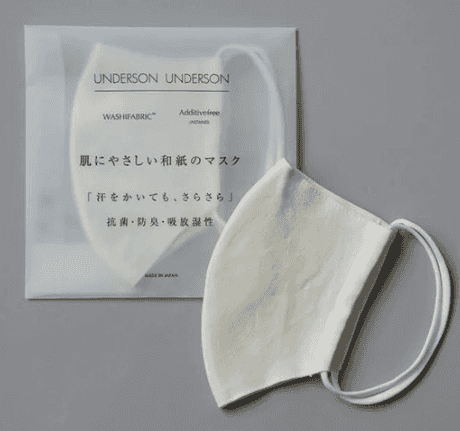

Primary packaging

Most products have several layers of packaging. The innermost part is the ones in contact with the products. These are called primary packaging. Their task is to hold and protect the actual products.

PE plastic bag

PE plastic is an organic compound formed by the addition polymerization of ethylene. Polyethylene is recognized as the best material in the world to handle food. It’s non-toxic, tasteless, and odorless: properties that are aligned with food packaging hygiene standards. PE film is light, transparent, and resistant to moisture, oxygen, acid, and alkali. It’s also a good insulator of heat and able to withhold vacuum. One of the most widely used applications of PE plastics is plastic bags. The body of the bag is soft and transparent, which is unique to PE plastics. It also has excellent resistance to tear hence it doesn't burst easily!

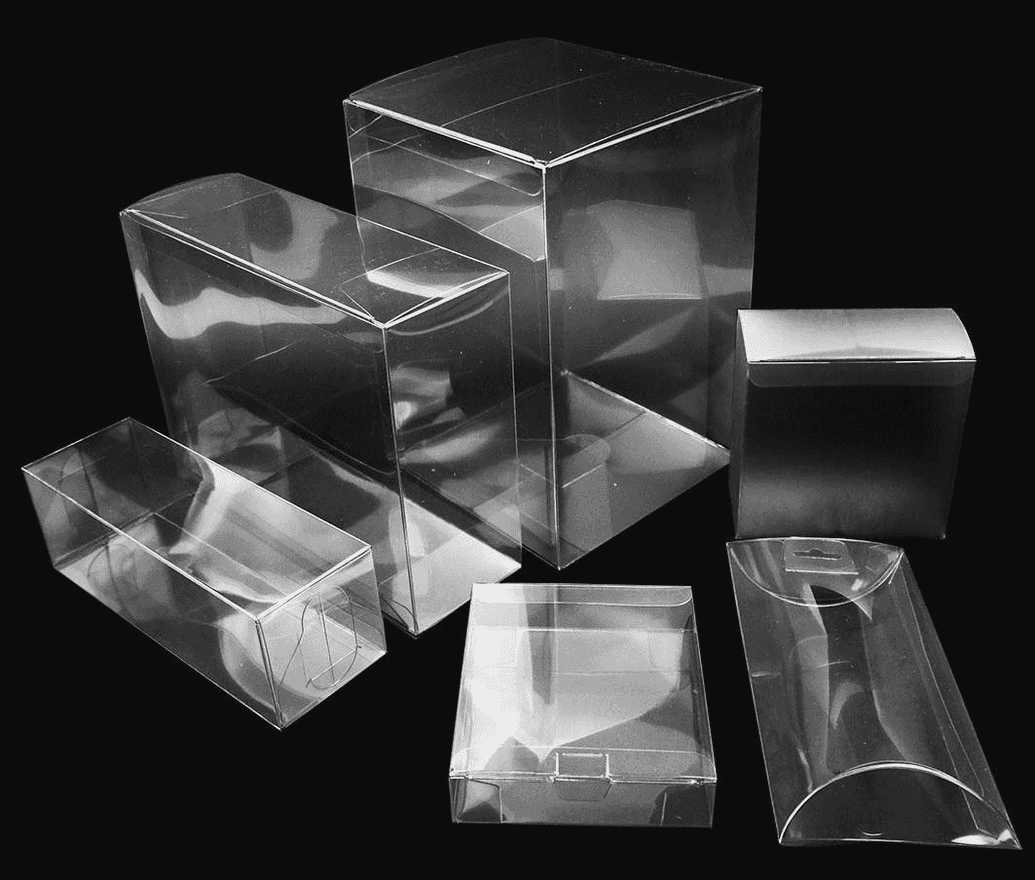

OPP plastic bag

OPP plastics are the most translucent (with the best transparency) material to be used as packaging. It is dust-proof and since it’s one of the most transparent materials, it can fully display the products inside. It is usually used as the outer packaging of commodity sales, which not only protects but also gives the product an aesthetic feature. OPP plastics are widely used for jewelry, stationeries, toys, tableware, kitchen utensils, and clothing. The bag body is the most brittle, has the highest transparency, and has insufficient pulling force, but it is most prone to bursting, and the printing is the easiest to decolorize.

Blister card

Blister card often referred to as BC, is made by heating and softening a piece of flat plastic hard sheet. It is then placed onto the surface of a pre-made mold to form its shape during the cooling process in a vacuum.

Bubble bag

A bubble bag is made by cutting high-pressure polyethylene bubble film into shape, before putting it in a specialized machine that heats up, dries, and cuts the film to form a bag. It's often used for electronic products as a shock absorber, cushion, or buffer packaging.

Shielding bag

A shielding bag is used to isolate items from the external electrostatic field, prevent static electricity in the bag, protect items from electrostatic hazards, and prevent electromagnetic interference. It is used for static-sensitive components such as PCB and LED.

Anti-static bubble film

It is made of low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE) with antistatic agents added to the film by bubble blowing. Other than as a shock absorber and cushion, it also plays a role to prevent static electricity from damaging the products inside.

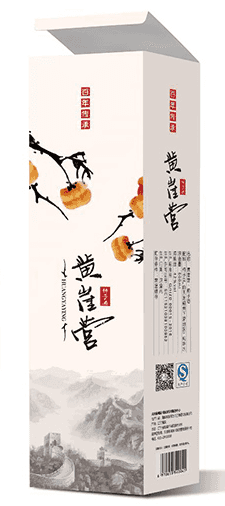

Secondary packaging

Secondary packaging is usually one that conveys information and description about the products to the customers. They are often designed as marketing material.

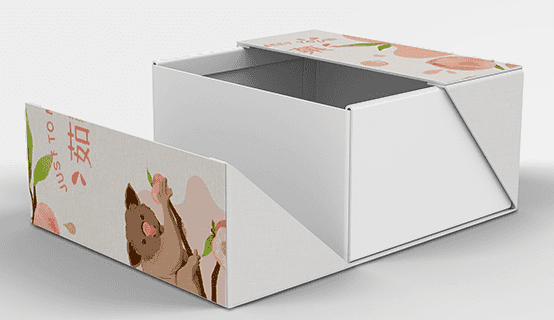

Printed or colored box

These could be done either in corrugated boxes or non-corrugated carton boxes.

Plain brown corrugated box

Usually, either 3-layer corrugated boxes or 5-layer corrugated boxes are used. Once the product is installed inside, the box is usually further sealed with tape.

Plain white box

These could be either corrugated (3 or 5 layers) or non-corrugated carton white boxes. A tape is usually also used to secure the goods.

Display box

There are many types of display boxes, such as color-printed display boxes and boxes with PVC covers, through which the products in the box can be seen.

PVC box or bucket.

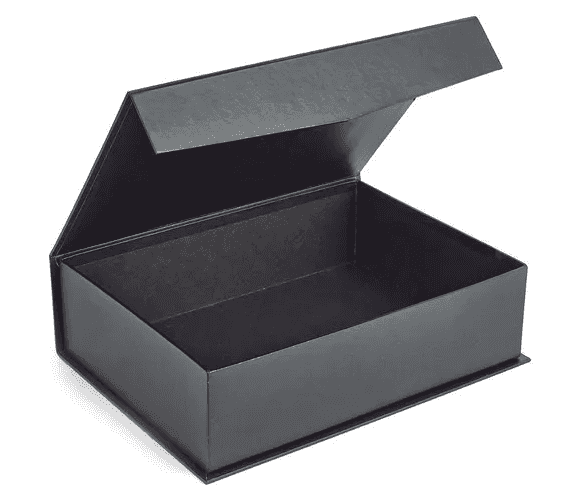

Tertiary packaging

The third type of packaging is usually meant for shipping and warehousing. It's also known as the shipping box. It usually has some labels on it to indicate the information of the products contained.

Types of Packaging Boxes

Telescope Design Boxes

Airplane Folding Box or Mailer

- Slide (or sliding) Box

- Front Tuck Rigid Boxes

- Folding Box

- Double-lid Box

- Slotted Folded Carton

- Special-shaped Carton Box

Printing process

UV Printing

It is a screen printing process that enhances the dazzling effect of printed products by partially coating UV varnish on the surface of the carton. The commonly used methods of UV printing are Full UV and Partial UV printing. Based on the varnish used, the output could either have a glossy finish or a matte finish.

Hot Stamping or Heat Transfer Printing

The color used for the process is mainly silver. A combination of gold, silver, and black is used to obtain various colors.

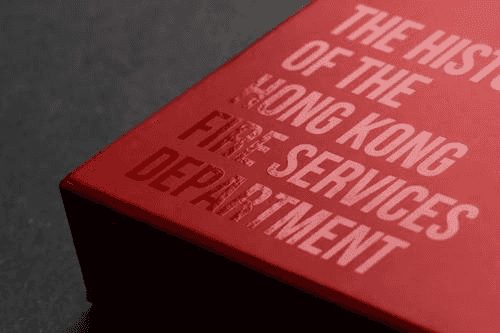

Embossing and Debossing

Embossing and debossing are unique methods to create textures on the surface of a product. It uses a concave-convex mold to deform the surface by pressing it at a certain pressure.

Lamination

Lamination is done by putting a layer of plastic film to protect a product's surface. Common laminating materials are glossy films, matte films, silk films, crystal films, laser films, holographic films, etc. The glossy film gives the surface a shiny color and a smooth feel, whilst the matte lamination provides a soft color, a misty surface, and a matte feel.

Gold or Silver Color Printing

If you want to print gold without bronzing, you can use spot color ink to print. Pure gold can't be printed using the four CMYK colors, but you can print a relatively close gold color with PANTONE.

Spot Color Printing

The process refers to the printing process in which other color inks other than yellow, magenta, cyan, and black (CMYK) ink are used to produce the color.

Cutting

Die-cutting indentation uses steel knives and wires to form a cutting template, then processes the printed product to the required shape by asserting a certain pressure.