Assembly Types and Levels

The process of assembly is continuously being evolved with the aim to improve the quality and speed of production. In the early stage of the development of the machinery manufacturing industry, operations such as filing, grinding, scraping, hammering, and tightening screws were used for assembly to make parts fit and connect. In 1789, Eli Whitney from the US had manufactured 10,000 muskets with interchangeable parts, relying on special fixtures to enable unskilled child laborers to engage in assembly work, greatly shortening the working hours. In the early to mid-19th century, interchangeable assemblies were gradually extended to products such as clocks, small arms, textile machinery, and sewing machines. At the same time as the development of interchangeable assembly, the term assembly line was also developed, and then by the beginning of the 20th century, a relatively complete automobile assembly line appeared. Following all these developments, the process of automated assembly that we use now was also developed.

General Assembly Terms

A product is made up of numerous parts and components combined together. The labor process of joining several parts into a component or joining several parts and components into a product is called assembly. The former is called a component assembly and the latter is called a general assembly.

Components are the most basic units that make up machinery and participate in the assembly.

Most components are pre-assembled into modules, subassemblies, and smaller parts before entering higher-level assembly units.

A module is an assembly unit that is one level larger than a part. The following cases are all combinations:

- Two or more parts are joined together by non-detachable joining methods (such as riveting, welding, hot pressing assembly, etc.).

- After a few parts are combined, they need to be combined and processed, such as the gear reduction box and the cover, the diesel engine connecting rod and the connecting rod cover, all of which are combined after the boring, and the parts are seated according to the number and cannot be interchanged.

- Group together with a datum part and a few parts.

A part is a combination of one or more components and several modules.

A subassembly is made up of a reference part and several components, modules, and parts. Such as spindle boxes, toolboxes, etc.

An assembly (general assembly) is a relatively larger integration than the component concept, a device with a complex mechanism, usually containing several assemblies, such as an excavator, with a chassis assembly, a main engine box assembly, an Arm working mechanism assembly, hydraulic power system assembly.

Generally speaking, the final assembly is greater than or equal to the assembly, depending on how complicated the equipment is. If the assembly needs to be expressed at a higher level, it can be reflected in the final assembly. The final assembly reflects the significance of the whole machine.

Method of Assembly

The method of assembly includes the steps and sequences, technical requirements, and inspection methods conducted on the parts and components done during the assembly process. These processes should be documented along with the selection of types of machinery and fixtures, the time taken, and the quota required for the whole assembly process. There are 4 types of assembly methods: interchange assembly, group assembly, repair, and adjustment.

- Interchangeable assembly

In the interchangeable assembly method, the assembly accuracy mainly depends on the manufacturing accuracy of the parts. According to the degree of interchangeability of parts, it can be divided into complete interchange assembly and statistical interchange assembly.

- Completely interchangeable assembly method The completely interchangeable assembly method is suitable for assembling mechanical structures with a small number of rings or with low assembly accuracy requirements in batch production and mass production. The advantages are stable and reliable quality, simple assembly process, high assembly efficiency, easy to realize automatic assembly, and convenient product maintenance.

- Statistical interchange assembly method (incomplete interchange assembly method) Compared with the complete interchangeable assembly method, the incomplete interchangeable assembly method has the advantage that the tolerance of the parts can be enlarged, so that the parts are easy to process, the cost is low, and the purpose of interchangeable assembly can also be achieved. The disadvantage is that the assembly accuracy of some products will be out of tolerance. This requires remedial action or economic justification.

Plastics Assembly

Fastener connection Fastener connection refers to the application of fasteners to connect plastic parts, including press-in fasteners, self-tapping screws and bolt connections. Commonly referred to as a press-in fastener, a plastic piece is connected by some kind of protrusion on its stem that forms an interference fit with the plastic cavity. Self-tapping screws use self-tapping threaded connections.

Adhesive connection

The adherents are held together by the adhesion of the glue. Commonly used glues are instant glue, UV glue, hot melt glue, silica gel, and so on. By applying different glues, to achieve different requirements for products, such as strength, waterproofing, sealing, chemical resistance, beautiful appearance, etc.

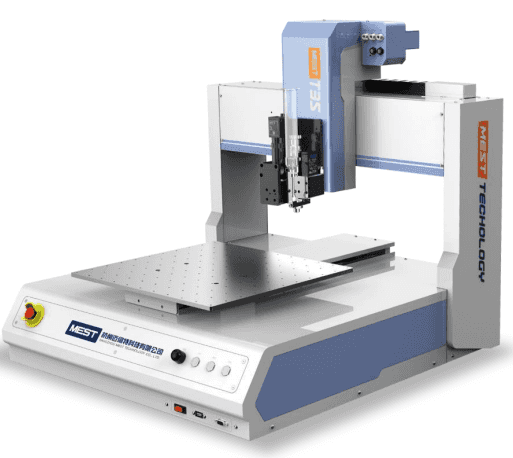

With the rapid development of automation technology, manual dispensing has been far from meeting the needs of the industry and has been gradually replaced by automatic dispensing machines. Automatic dispensing machines are widely used in industrial production, such as integrated circuits, printed circuit boards, electronic components, auto parts, handbags, packaging boxes, etc. The application of an automatic glue dispensers greatly improves production efficiency, improves product quality and uniformity, and can realize some processes that cannot be completed by manual glue dispensing.

NexPCB has been equipped with an automatic glue dispenser with a reliable production standard.

Snap connection

Snap connection is a mechanism used for embedded connection or integral locking of one part and another part, usually used for the connection of plastic parts, and its material is usually composed of plastic material with certain flexibility. The biggest feature of snap connection is low cost, flexible design, easy installation, and disassembly, so it is also a very common connection method in plastic products.

Welding (ultrasonic, vibration welding)

When plastic is given high-frequency vibration, the vibration energy is converted into heat energy by friction, which causes the contact surface of the two plastics to melt rapidly, and after a certain pressure is applied, they are fused into one. Afterward, stop the ultrasonic vibrations whilst still holding the pressure for a few seconds to wait for the plastics too. A strong molecular chain will be then formed from the welding process. Using this method, the strength of the welded bond will almost be the same as the strength of the raw materials.

Hotwire welding

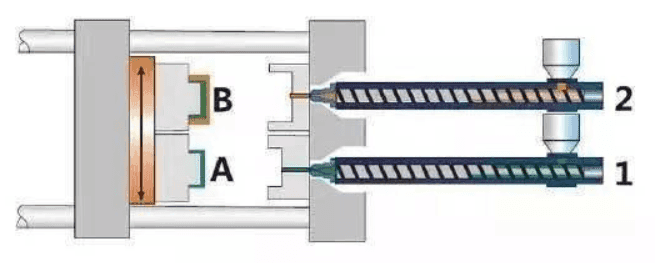

Hotwire welding, also known as resistance welding, uses a wire to transfer heat between two connected plastic parts to melt the surface of the plastic parts and apply a certain amount of pressure to join them together.

The wire is placed on one of the surfaces in the parts to be connected, and when an electric current is passed through the wire, its resistance is used to make the wire generate heat and transfer the heat to the plastic part. After welding, the wire remains in the plastic product, and the part that sticks out beyond the joint is cut off after welding. Generally, grooves or other positioning structures are designed on the part to ensure that the wire is in the proper position.

Insert molding

Insert molding refers to the molding method in which pre-prepared inserts of different materials are placed in the injection mold and then resin is injected, and the molten material is bonded and solidified with the inserts to form an integrated product.

Among them, thread inserts are the main way to generate threads in plastic parts, which can provide better connection strength than self-tapping threads. Inserts are not limited to metals, but also include cloth, paper, wires, glass, wood, coils, and electrical parts. Insert molding utilizes the combination of insulating and conductive materials of resin to produce molded products that meet the basic functions of electrical products.

The advantage is that the easy formability and flexibility of the resin and the rigidity, strength and heat resistance of the metal complement each other to make a complex and delicate metal-plastic integrated product.

Multi-Part Molding Also known as two-color injection molding, a molding method in which plastics of different colors and materials are injected into the same mold.

Assembly Levels and Costs

Small batch production

It is not recommended to use two-color injection molding, as its mold requirements are relatively more complicated than the other types of injection molding. Hence, the cost of initial investment will be higher.

If you're only doing for small batches of goods, using two-color injection molding is often not enough to make ends meet. As an alternative, you can consider snap connection or insert molding as two of the better options.

Hence, rating the best connection options for your early stages, from best to worst would be:

Fasteners, Adhesives, Welding > Inserts, Snaps >> Multi-Part Molding

Medium volume production

At this stage, you have many choices. What assembly form to choose often depends on what goal you want to achieve, do you want to improve the appearance? Waterproof performance? The integration of the whole product? Or reduce costs? To choose what kind of procedures you should undertake, you can consult NexPCB. Our engineers will guide you and give you tips to achieve the best option for your project.

Mass production

At this stage, most often, you'll focus more on how to control your costs. The processes you take at this stage will very much correlate to the initial process option you took during the small production stage.

Hence, choose carefully from the beginning!

Multi-Part Molding > Snaps - Inserts > Fasteners - Adhesives - Welding

The assembly process that NexPCB has done the most is fastener connection, our company is also equipped with a screw machine, which is suitable for conventional fastener assembly. A fastener connection is the most commonly used connection form since it can be easily disassembled for maintenance. However, its assembly speed is relatively slow. It's also not suitable to be used in a vibrating or shaking environment for a long time, since it has a high risk of falling off.

NexPCB is also very experienced in connection-making processes such as using snap connections, ultrasonic weldings, adhesive connections, inserts, and multi-part injection moldings -- with mature cases for the processes.

Regarding the specific steps of these processes, the steps taken to create connections are usually as follows:

- A structural engineer will issue professional engineering drawings for the products.

- The quality management team will control the risks of the machining processes.

- The purchasing manager will send the engineering drawing to our manufacturers and suppliers for mold, injection molding, ultrasonic welding, and various mechanical equipment requests.

- At the same time, our structural engineer will point out the main points of the production process.

Structural engineers are the people who usually assist in the "Design for Manufacturing & Assembly", or DFMA. They usually have the best understanding of the industry, product, structure, manufacturing processes, and assembly processes.

However, the responsibility is not always borne by the structural engineers alone. Factors such as design issues, production issues, assembly issues, or component selection issues might require different parties to be more involved as well.

Since the design you make will be targeted for the mass production process for marketing, it's very important to create a strong foundation and a well-designed process from the initial stages. Pay enough attention and decide well on your first steps, so you can achieve a healthy production process in the future