Anti-static (ESD) Packaging

What is anti-static (ESD)

ESD (Electro-Static discharge) is a discipline formed in the mid-20th century to study the production, risk, and protection of static electricity. Hence, the population has become accustomed to calling electrostatic protective equipment ESD.

Normally, electrical appliances ESD only shows an extremely low capacitive reactance (generally <5pf), which has no effect on its operation. However, when a device reaches the predetermined breakdown voltage, it responds quickly (nanosecond level) and amplifies the leakage current between electrodes in a geometric progression, which absorbs and weakens the interference and influence of static electricity on the circuit.

Due to the particularity of the constituent materials of the ESD electrostatic resistor, ESD often achieves electrostatic protection for the equipment by absorbing and dissipating static electricity, that is, a charging and discharging process, so the ESD in the equipment Electrostatic resistors are not easily damaged by aging.

The generation of static electricity

Static electricity is a natural phenomenon that can be generated in various ways, such as contact, friction, induction between electrical appliances, etc. Static electricity is portrayed to have a high voltage, low power, small current, and very short action time. You'll also need a long time to generate static electricity.

When a human body or different objects touch or rub and then leave each other, thousands of volts or even tens of thousands of volts of static electricity can be generated.

The hazards of static electricity:

Static electricity causes serious harm in many fields. Friction electrification and human body static electricity are two major hazards in the electronics industry, which often cause unstable operation or even damage electronic and electrical products. For some sensitive instruments, this voltage may be a fatal hazard.

What is anti-static packaging:

Anti-static packaging is a type of packaging used to protect electronics, chips, and other devices against static electricity. They're usually made up of static dissipative or anti-static materials.

Main categories:

There are many anti-static packaging products, including:

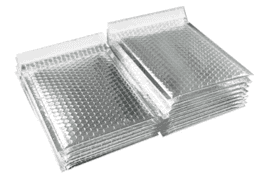

- Anti-static bag:

It's made up of a two-layer composite or a higher four-layer structure. The Faraday cage induction cover effect is formed in the bag, which protects the items in the bag from the electrostatic field to the greatest extent, prevents the accumulation of static electricity, and avoids static electricity hazards. It is often used in the packaging of electronic components to prevent damage caused by static electricity that is prone to occur in electronic components. Commonly used are open buckle and closed

Advantages:

+ Anti-static

+ Anti-radio frequency

+ Waterproof vapor penetration

+ Anti-salt spray, etc.

Features:

* The outer layer is made of transparent anti-static material, and the middle is a translucent conductive metal layer.

* The appearance is silver-gray and translucent, and the packaged objects can be seen through.

* It can be made into flat bags, zipper bags, organ bags, three-dimensional bags and other forms.

* Widely used in static-sensitive electronic products such as computer motherboards, sound cards, and graphics cards.

From left to right: open type, self-sealing type

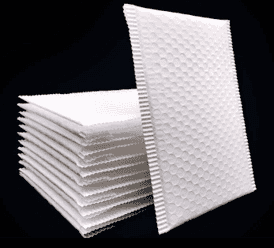

2. Anti-static bubble bag:

Packaging for lighter products and products with general requirements. Its characteristic is to achieve the shockproof and buffering effect through this sealed airbag, and at the same time, it can also imitate static electricity to a certain extent (generally, self-sealing and opening are commonly used).

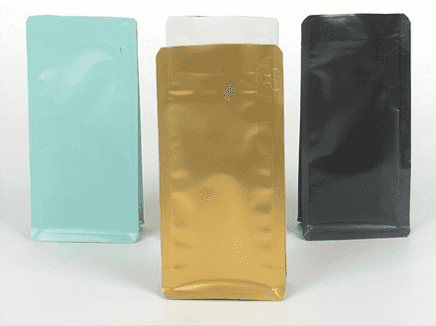

3. Foil bag:

Foil bag, or aluminum bag, is actually an aluminum-plastic composite vacuum packaging bag. It can be well protected from moisture, light, water, oxygen, high temperature, or low temperature, and the shape is stable. It can also avoid the accumulation of electrons in the product during the friction movement, which will cause discharge and cause damage to static-sensitive products. It also has the effect of blocking the mutual interference effect of different electromagnetic fields on the product. And without restrictions, the size and style can be customized according to the volume. (flat mouth, three-dimensional bags, organ bags, etc.).

Points to note: The product contained needs to be tested by GB and ASTM standards, and the product meets the requirements of environmental protection (a third-party test report can be provided)

4. Aluminum bag:

This bag is formed by evenly distributing high-purity aluminum on plastic under high temperature and vacuum. The production cost of aluminum foil bags is higher than that of aluminum-plated bags, and there are obvious differences in the process between the two.

A variation of this aluminum bag is the aluminized bubble bag. Its outer layer is made out of aluminized film (multiple colors) with a smooth surface. You can print different patterns, trademarks, or labels based on your required design. Its inner lining is filled with bubble film, as a shock-resisting material. It aims to cushion and protect the product from being damaged due to high pressures or rough handling.

5. Anti-static foam:

It is processed by adding an appropriate amount of conductive substances to plastics. The hard type is used for inserting integrated circuit chips, and the soft type is used for anti-static packaging. Anti-static foam is a dissipative material between conductive and insulating materials.

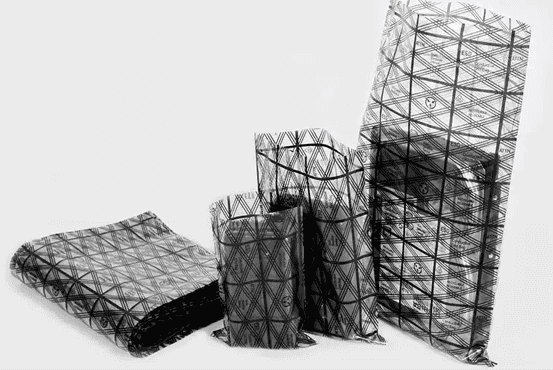

6. Anti-static mesh bag:

Blow molded from LDPE and LLDPE, with anti-static properties and an intuitive understanding of the contents. Comply with RoHS standards (environmental protection, pollution-free, recyclable) and international anti-static testing standards; color, size, opening method, etc. can be customized.

Advantages:

+ It has good barrier properties, heat insulation properties, anti-oxidation, waterproof and moisture-proof.

+ Strong mechanical properties, high blast resistance, strong puncture, and tear resistance

+ High-temperature resistant, low-temperature resistant, oil resistant, good fragrance retention performance

+ Non-toxic and tasteless.

+ Flexible and transparent

+ Dustproof, antibacterial, moistureproof, etc.

7. Anti-static tray:

It is made of a special material blister and PP plastic, and the resistance value of the surface of the material is below 10 to the 6th power or from 10 to the 11th power ohm. Due to the addition of special polymer chains in the raw materials, the finished product has permanent static dissipative properties. The finished product has good mechanical strength and heat resistance; good impact resistance and strong chemical corrosion resistance. It will not change its antistatic performance despite the changing environment, time, and temperature.

Advantages and features:

+ Anti-bending

+ Anti-aging

+ High load-bearing, tensile, and compression strengths.

+ Lightweight, durable, and stackable (easy storing)

Anti-static trays are usually available in a box-type turnover box, which can be used for both turnover and finished product shipment packaging. Various specifications and sizes can be customized according to user needs and can be lined with covers, dust-proof sheets, anti-static sheets, or have it printed for aesthetics.

Generally, the anti-static tray is designed and manufactured according to the size provided by the customer to achieve the most efficient loading. Sometimes, you can also use the same trays in the factory to increase the storage capacity of electronic components, PCB boards, and dust-free workshop components. Hence, saving production costs.